Senscient ELDS trace laser gas analyzer

A unique laser optical gas analyzer providing high selectivity in combination with other technologies for monitoring gas leaks.

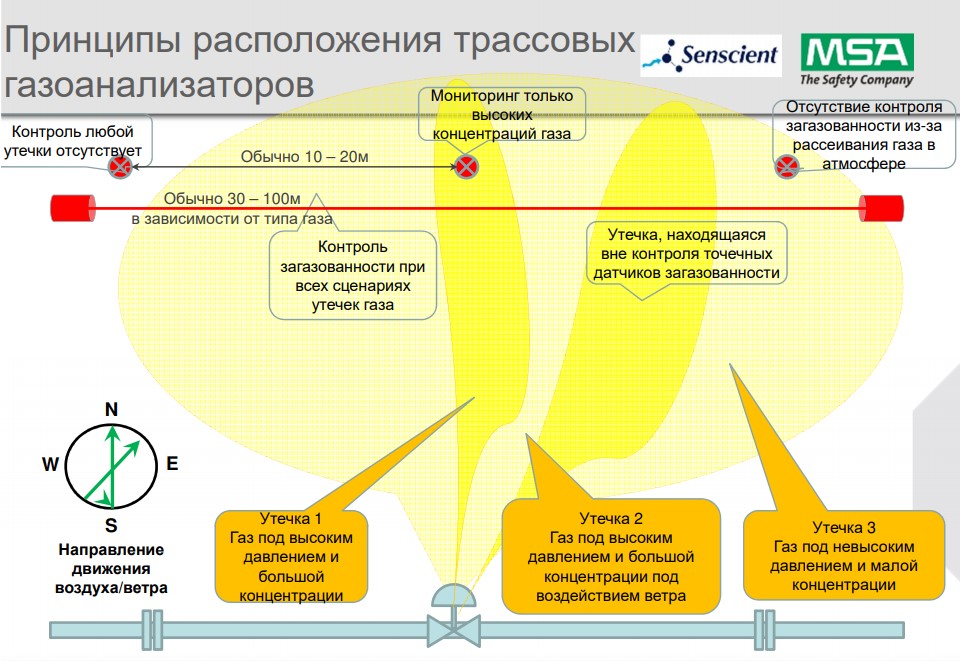

Increases the probability of detecting leaks, bringing it closer to 90-95%.

There is no analogue on the Russian market.

When using only point gas contamination sensors, the probability of detecting leaks is in the region of 50-60%.

Detects leaks at a distance of 40-60m.

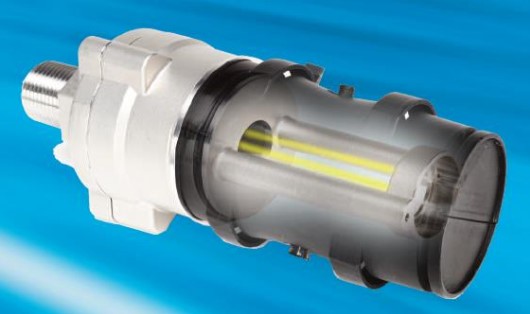

An open path laser gas analyzer for the detection of toxic and flammable gases. The receiver with separate transmitter is certified for use in hazardous areas.

It is used to detect gases both in open areas (at a distance of 5– 200 m, depending on the gas) and in air ducts (0.5– 5.0 m, only for methane).

Key features:

- Designed to detect target gas, eliminating false alarms

- Fast response speed (less than 5 seconds) allows quick initiation of protective measures

- Daily automatic self-test, eliminating the need for regular manual checks

- Factory calibration allows you not to perform periodic calibration during the entire life of the device

- The absence of consumable sensing elements results in lower operating costs!

Measured gases:

- Hydrogen sulfide

- Ammonia

- Hydrogen fluoride

- Carbon dioxide

- Hydrogen chloride

- Methane

- Ethylene

ELDSTM = Enhanced Laser Diode Spectroscopy The measurement method is high intensity diode laser spectroscopy.

ELDSTM systems architecture

Identical architecture with differential infrared tracers ... but with more capabilities.

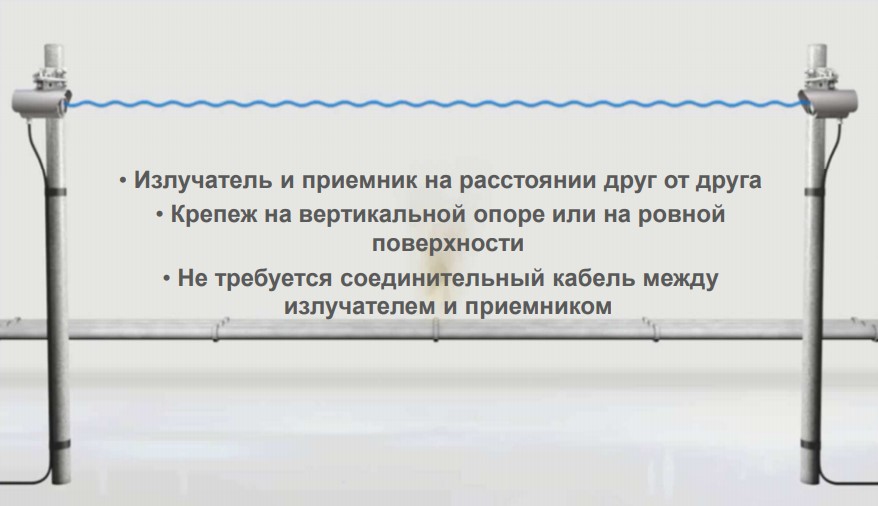

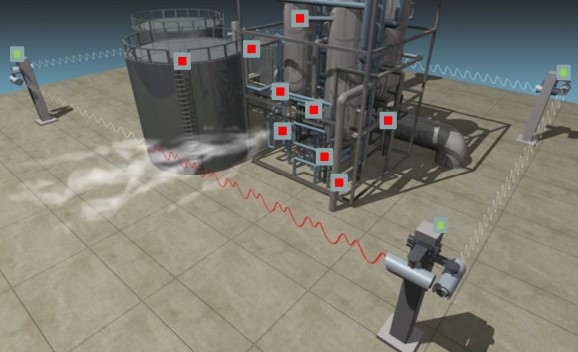

Installation options for line gas analyzers

- Red - Spot gauges - close to sources of leaks or confined areas

- Green - On-route gas analyzers - in open areas, along pipe racks, perimeter control, as well as in ventilation and air conditioning systems.

Reduced installation and maintenance costs, improved safety.

ELDSTM - Installation Options

- ELDS system architecture

- Location of detectors

- Location principles

- Installation options and practical examples

- Distinguishing features and philosophy

- ELDSTM technology success engines

Chuandongbei gas project in China

- A joint venture between Chevron and CNPC

- Gas production

- Availability of H 2 S

- 236 pcs of ELDS TM gas analyzers installed for perimeter monitoring

- H 2 S up to 60m optical path length

- CH 4 up to 200m optical path length

- 0-1500 ppm.m H2S

- 0-1 LEL.m CH 4

Solved problems with ELDS TM technology

- Reliable alarm - no false alarms, but if the thresholds are exceeded, ELDS TM initiates initiates measures to evacuate residents of neighboring villages

- Continuous perimeter monitoring - ELDS TM allows you to protect against an increase in the concentration of hydrogen sulphide in the air and monitor the MPC with appropriate response thresholds

- No routine maintenance required - optical technology, no consumables

Terra Nova platform in Canada

- Suncor platform operator

- A lot of fogs

- 158 pcs. ELDS TM gas analyzers installed for monitoring long areas and on air ducts

- Combined gas analyzers for H 2 S and CH 4

- Sensitivity; CH 4 0-1 LEL.m

- H2S 0-500 ppm.м

- In air ducts CH 4 0-100% LEL

- Max. optical path length 40m

Major Issues Solved by ELDS TM Instruments

- Reduced Downtime - Conventional field instruments resulted in multiple shutdowns due to false alarms. ELDS TM instruments do not have false alarms due to fogging, resulting in savings of $ 5 million in the first year of operation.

- Reduced operating costs - no personnel required to service 158 instruments

Gryphon Alpha floating oil platform

Maersk Oil is the platform operator

- 24pcs ELDS TM devices were installed on the ducts

- Selective monitoring of CH4 in ducts

- Sensitivity; CH4 0-1 LEL * m

- A very strong and prolonged storm tested the efficiency of this technology in practice

Major Issues Solved by ELDS TM Instruments

- Lack of Operator Confidence - The bad weather on the platform caused countless false alarms and a lack of operator confidence in correct / incorrect alarms.

- After the installation of ELDSTM instruments, a storm that occurs 1 time in 100 years with such intensity and length took place. Even under such conditions, the devices worked with 100% reliability.

Alkylation Unit at Cheyenne Refinery

- HollyFrontier - Installation Operator

- Refinery with production of 52,000 barrels per day; reconstruction of the hydrogen production unit, including the alkylation unit Due to the difficulties with the selection of conventional electronic devices and the specific required measuring scale, the only solution was the ELDS technology

- HF 0-50 ppm*м

- Optical path length 60-120 meters

Major Issues Solved by ELDS TM Instruments

- Equipment and Maintenance Costs - the distances that need to be monitored to monitor HF MPCs in the vicinity of the alkylation plant left no options other than line gas analyzers. Plus, the ease of installation and maintenance of ELDS removed any doubts about the correct choice.

- Operating Costs - ELDSTM' s automatic self-test feature has eliminated the need for personnel to maintain these instruments.

Some clients